Industrial stainless steel pipe is an important pipe material commonly used in the industrial field. It has a wide range of applications and is of great significance. This article will discuss the characteristics, production process and application of industrial stainless steel pipes in the industrial field.

Industrial stainless steel pipes have several unique features that make them popular for industrial applications.

First, stainless steel pipes have excellent corrosion resistance. Its main component is chromium, which can form a dense oxide film to effectively prevent further oxidation and corrosion of the metal surface, thus having excellent corrosion resistance.

Secondly, stainless steel pipes have good mechanical properties. It has high strength and hardness, good tensile resistance and compression resistance, and can withstand large pressure and load.

In addition, stainless steel pipes have excellent processing and welding properties, making them easy to process into pipes of various shapes and specifications, and the connections after welding are strong and reliable.

The production process of industrial stainless steel pipes usually goes through the following main steps:

First of all, high-quality stainless steel raw materials are selected, and qualified stainless steel billets are obtained through smelting, refining and other processes.

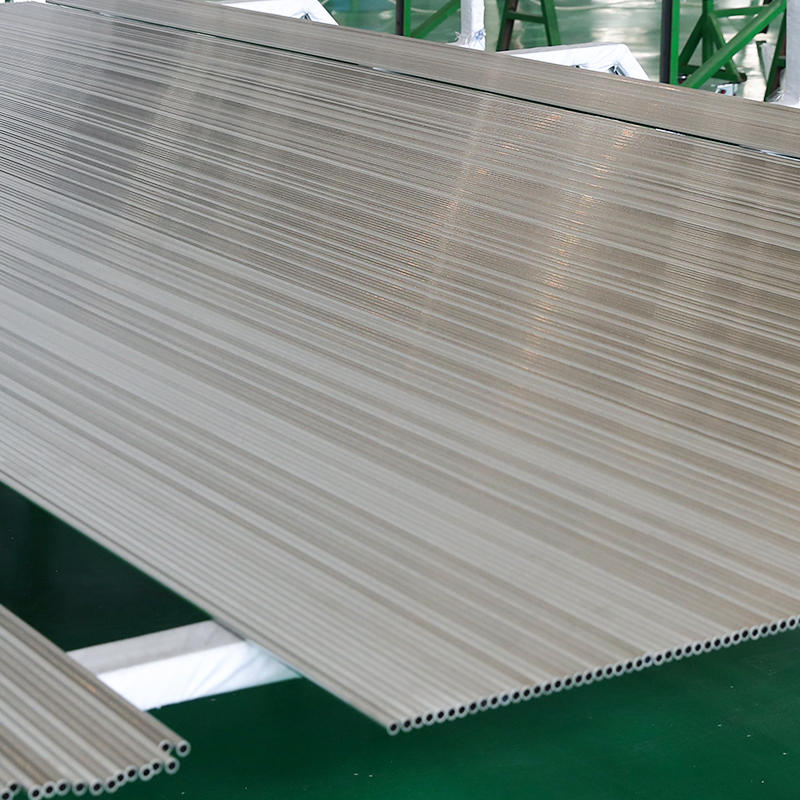

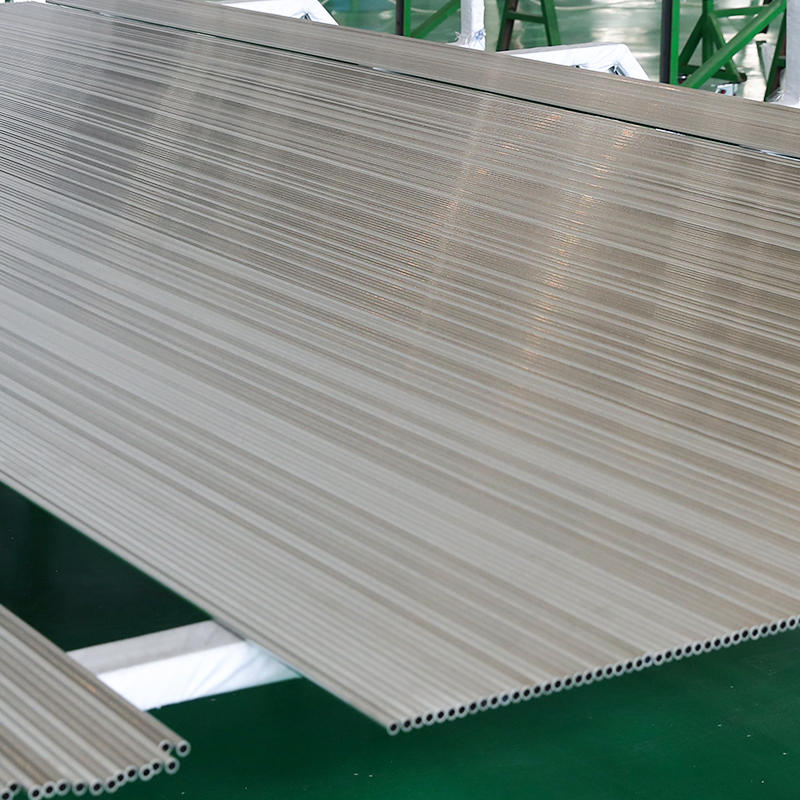

Then, the stainless steel blank is processed into the required tube blank through hot rolling, cold drawing and other processes.

Then, the tube blank is processed into the final stainless steel tube product through cold drawing, cold rolling, welding and other processes.

Finally, the stainless steel pipe is subjected to surface treatment, including pickling, polishing and other processes to improve its surface finish and aesthetics.

Industrial stainless steel pipes are widely used in industrial fields. It can be used to transport various liquids and gases, such as water, oil, gas, etc., and can also be used to manufacture various equipment and components.

In the chemical, petroleum, electric power and other industries, stainless steel pipes are often used in pipeline systems that transport corrosive media or work under high temperature and high pressure conditions.

In industries such as pharmaceuticals and food processing, stainless steel pipes are often used to transport high-purity liquids or food-grade substances and meet hygienic requirements.

In the fields of construction, transportation and other fields, stainless steel pipes are also widely used to manufacture various decorative, structural and piping equipment, such as railings, handrails, bridges, etc.

In general, industrial stainless steel pipes play an important role in the industrial field with their excellent performance and wide range of applications. With the continuous development of industry and the continuous advancement of technology, I believe that industrial stainless steel pipes will have broader development prospects.

中文简体

中文简体